Bridge Brothers has an integrated process to deliver your bridge on time and within budget. At Bridge Brothers, we offer the quickest turnaround times and the most competitive pricing. Our bridges are custom engineered to fit our clients’ application and specifications. Steel bridges, pedestrian bridges, trail bridges, industrial bridges, skyway bridges, or pipe racks, we fabricate bridges for any site. Bridge Brothers is represented by BBLM in the Philippines.

At Bridge Brothers, we offer the quickest turnaround times and the most competitive pricing. Our bridges are custom engineered to fit our clients’ application and specifications. Parks, trails, marine applications, or industrial access, we fabricate bridges for any site.

One project consultant shepherds each bridge from pre-construction, concept, design, engineering, manufacturing, all the way to installation, making sure any changes minimally impact the timeline or budget. This level of personalized interaction with our clients sets us apart from other firms.

Because Bridge Brothers is a fully integrated engineering and construction firm, we work with our clients to make sure each bridge is well engineered and aesthetically pleasing. Our engineers and architects work hand-in-hand with our clients to bring their vision to life. The team takes into consideration how and where a bridge will be used to advise on materials and configurations that would be appropriate. From the project specifications and from conversations with the client team, a unique bridge emerges.

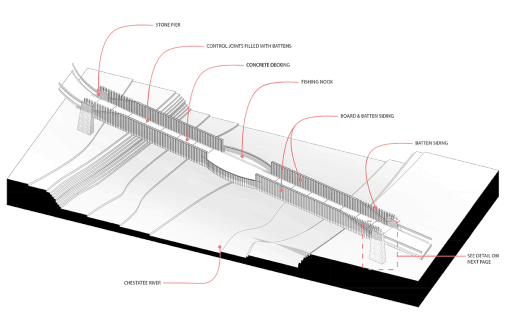

Once the client and team agree on the conceptual design for the bridge project, our in-house architects create a more detailed rendering. We use the latest technology to develop an image that’s a realistic 2D or 3D vision of the project. Depending on the type of visualization, the client can rotate around the bridge, zoom in to see the finest details, and visualize how well the bridge integrates into its surroundings.

During the design phase, our experts will be able to identify any potential structural or design flaws that may impact fabrication or installation. We value an interactive design process and our architects and engineers enjoy walking clients through the technical aspects of a project. Design is an integrative process and Bridge Brothers is happy to make modifications on a design.

Our civil and structural engineers are certified P.E. licensed in all 50 states. Beyond structural and site engineering solutions, we also provide the following services on every project:

- CIVIL & SITE ENGINEERING (site design including grading and abutment design)

- VE SOLUTIONS (value engineering analysis on each project to improve the bridge’s quality and lifespan while reducing costs)

- LIFE CYCLE COST ANALYSIS (finding the most cost-effective strategy per project from fabrication to disposal)

Once a project has gone through several iterations of design and engineering, the custom components of the bridge are manufactured. Bridge Brothers uses prefabrication to keep timelines short and costs low. From the concept phase through manufacturing, we ensure that our clients receive quality materials at competitive prices.

Our teams are highly skilled in sourcing and working with high-quality materials and fabricating well-built structures. Bridge Brothers has shops which allows us to start work on a project immediately. Big or small, we provide top of the line manufacturing services for each project.

Prefabrication doesn't mean off-the-shelf. Each bridge is custom-built. The pre-fab process simply means that the bridge is assembled by section in a controlled environment then are transported and assembled onsite.

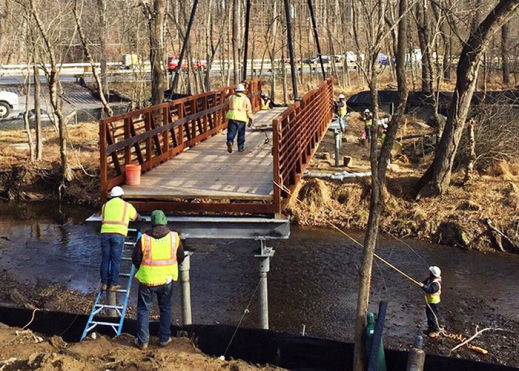

Building the bridge in dedicated sections helps reduce the need for a large construction project, thereby cutting down overall project cost. A project saves money by hiring a smaller crew and only using the equipment needed for installation.

Projects using the pre-fab process tend to be completed faster than bridge projects built onsite piece by piece. In a controlled environment, the manufacturing team can simultaneously work on multiple aspects of a bridge. On a traditional bridge building construction site, workers often need to wait for one part to be completed before proceeding. A delay in one area creates a ripple effect and can threaten a deadline and increase costs.

Finally, pre-fab is safer for workers and the environment. With quicker construction focusing solely on installation, work crews spend less time on the job site and are thus less likely to sustain injury. Pre-fab has a positive impact on the environment by limiting pollution and possible contamination caused by larger construction projects.

A quick installation process helps clients avoid lengthy shutdowns to a business, industrial factory, or recreational area during construction.

Because Bridge Brothers uses the prefabrication manufacturing method, installation process is quick and seamless. Building each bridge in prefabricated sections saves time by reducing the onsite construction period and avoiding unforeseen delays. Our team handles the bridge from design to installation. Our bridge consultants are familiar with the bridge and stay in constant communication with the installers to make sure the bridge is put in properly and without incident.

Bridge Brothers also offers site construction services so that you only have one contractor to work with. If you use this service, Bridge Brothers will handle the construction and configuration of structural site elements like helical piers, abutments and other elements required to integrate your new bridge into the site.

A modular steel bridge is designed to carry the weight of vehicles. Strong and lightweight, these bridges allow you to bridge a road over a stream, railroad, or gulch inexpensively and easily. Modular steel bridges are designed to carry standard highway loads and they can be single or multiple lanes.

Modular steel bridges are designed to be simple. They usually consist of a simply supported structural system in which the bridge is only supported by a pier or abutment at each end. These types of bridges are found all over, in a variety of applications.

Modular steel bridges can be permanent or temporary. Some municipalities will use a temporary modular steel bridge for a road detour, for example. A modular steel bridge can also be a permanent road bridge for an urban or rural area. A modular steel bridge can be utilitarian, or it can be designed in a way that it becomes an icon of your community. Options with modular steel bridges include sidewalks and utility corridors, as well as more architectural details like truss panels.